How to choose the right material for superior dental prosthetics ? – Join us at Krakdent 2025

Talk live with our team at Krakdent 2025

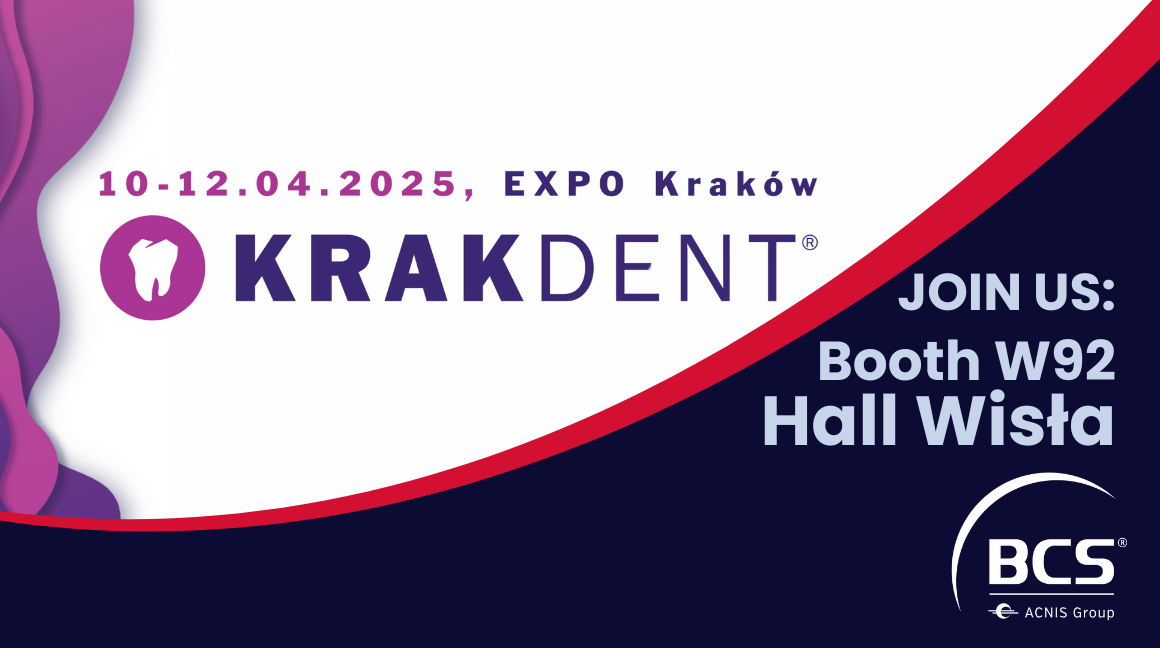

We are thrilled to announce our presence at Krakdent 2025 —the largest dental fair in Poland. Let’s discuss your projects and introduce you to our latest advancements!

Event details:

📅Dates: April 10-12, 2025

📍Location: International Exhibition and Convention Centre EXPO Krakow, Kraków, Poland

🙋 Our Booth:Hala Wisła / W92

How to choose the right material for superior dental prosthetics ?

Choosing the right material is key to optimizing production. With a carefully chosen and well-characterized powder, you benefit from:

- Optimal density and excellent surface finish

- Precise, tension-free framework

- Excellent powder flowability

- High productivity and rapid prototyping

Our expert support helps guide your choice

By thoroughly analyzing powder characteristics, we help you select the optimal material for your process – ensuring reliable and high-quality additive manufacturing results. Our in-house powder characterization service offers:

- Precise powder validation for optimal performance

- Fine-tuned printing parameters for consistent results

- Full compliance with industry standards

Our specialized range of certified products

To meet the highest standards in dental manufacturing, we offer a range of high performance discs and powders:

For additive manufacturing

BCS develops metal powders compatible with major additive manufacturing processes including: LPBF (Laser Power Bed Fusion / Sintering), EBM (Electron Beam Melting), BJ (Binder Jetting). Our powder stock includes:

- Titanium Nicrallium Ti6Al4V ELI (grade 23)

- Cobalt-Chrome Nicrallium N7

- Cobalt-Chrome Nicrallium N4

For CAD/CAM milling and machining

CAD/CAM technology simplifies the micro-machining of dental prostheses such as crowns, veneers, inlays and onlays, fixed dental bridges, dental implant restorations, and both removable and fixed dental prostheses. For these dental applications, BCS offers discs in:

- Zirconia

- Titanium Nicrallium Ti6Al4V ELI (grade 23)

- Cobalt-Chrome Nicrallium N7

All our materials are ISO 13485:2016 certified and comply with CE marking requirements for medical devices, guaranteeing safety, traceability, and performance.

Reliable supply for seamless production

At BCS, we prioritize product availability and fast shipping to help you maintain a seamless and efficient production workflow. Contact us for more information.

Join us to discuss how our advanced materials and expert services can enhance your dental production process.

We look forward to seeing you from April 10th to 12th at Krakdent at stand W92 Hall Wisła.