NICRALLIUM® TA6V ELI – Grade 23 discs are made of a non-precious, titanium-based, type 5 machining and casting dental alloy for metal-ceramic restorations. This alloy is used for the manufacture of orthopaedic prostheses.

NICRALLIUM® is a registered trademark of BCS.

- SURFACE WORK OF THE ELEMENT

Work according to standards with clean and sound instruments. Blasting with 50u alumina using a non-recycled blasting machine is essential. The pressure should be 5 to 7 kg, the part should have a uniform matt appearance. The cleaning can be carried out with a steam jet (5 kg approximately) or 10-minute ultrasound in ethyl acetate or alcohol at 90°. In case of impurities, start again from the scraping phase.

Refer to the technical instructions of the ceramic manufacturer.

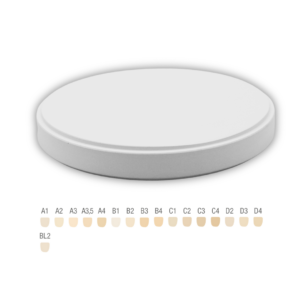

Sandblasting of the impression surface with 25 or 50μ alumina.

Polishing: rubber, pumice, paste and polishing cream.