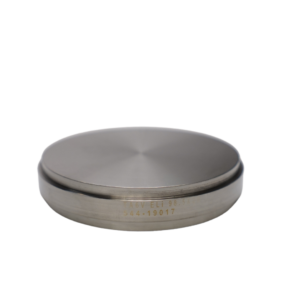

NICRALLIUM® N7 discs are made of a non-precious, nickel- and beryllium-free, type 5 cobalt-based dental alloy for metal-ceramic restorations.

The presence of molybdenum allows the alloy to be stable at high temperatures, facilitating the bonding with the ceramic.

It can also be used for the manufacture of dental and orthopaedic implants.

NICRALLIUM® is a registered trademark of BCS.